We’re in the era of instant gratification and demanding delivery timelines. The pressure is on the warehouses to operate at peak efficiency. Hence, there is no space for time-consuming processes. Modern warehouses require innovative solutions that streamline workflows, boost productivity, and ensure error-free operations. Smart warehouse lockers can be a game changer in this regard.

These aren’t your traditional lockers – they’re completely digitized systems that can be integrated seamlessly with your warehouse management system, offering a ton of benefits such as convenient package management, timely delivery, and productivity improvements. Let’s get deeper into the world of warehouse lockers, exploring their advantages, implementation process, and how they can enable optimal workflow at your warehouses.

Benefits of Warehouse Lockers

Warehouse lockers offer a multitude of advantages over traditional storage methods. Let’s explore some of the key benefits:

- Increased Efficiency: Warehouse lockers minimize picking and packing times to improve warehouse efficiency. Items can be pre-sorted and stored in designated lockers, allowing pickers to quickly locate and retrieve them, eliminating the need to navigate aisles and search for inventory.

- Improved Order Accuracy: Warehouse lockers equipped with barcode scanners or RFID tags enable real-time tracking of inventory. This reduces the risk of errors and ensures you’re sending the right items to your customers every time, making it an efficient warehouse.

- Enhanced Security: Warehouse lockers provide a secure storage solution for high-value items, sensitive materials, or controlled substances. Access can be restricted by user permissions, and audit trails can be generated for enhanced accountability.

- Space Optimization: Warehouse lockers often have a modular design, allowing you to maximize vertical space utilization within your facility. This is particularly valuable in warehouses with limited square footage.

- Scalability: As your business grows, your warehouse needs can evolve. Locker systems are easily scalable. You can add or remove lockers as needed to adapt to fluctuating inventory levels.

- Improved Inventory Management: Inventory data can be automatically updated with every item placed in or retrieved from a locker. This provides real-time insight into stock levels and helps prevent stockouts and overstocking situations.

Integrating Smart Warehouse Lockers

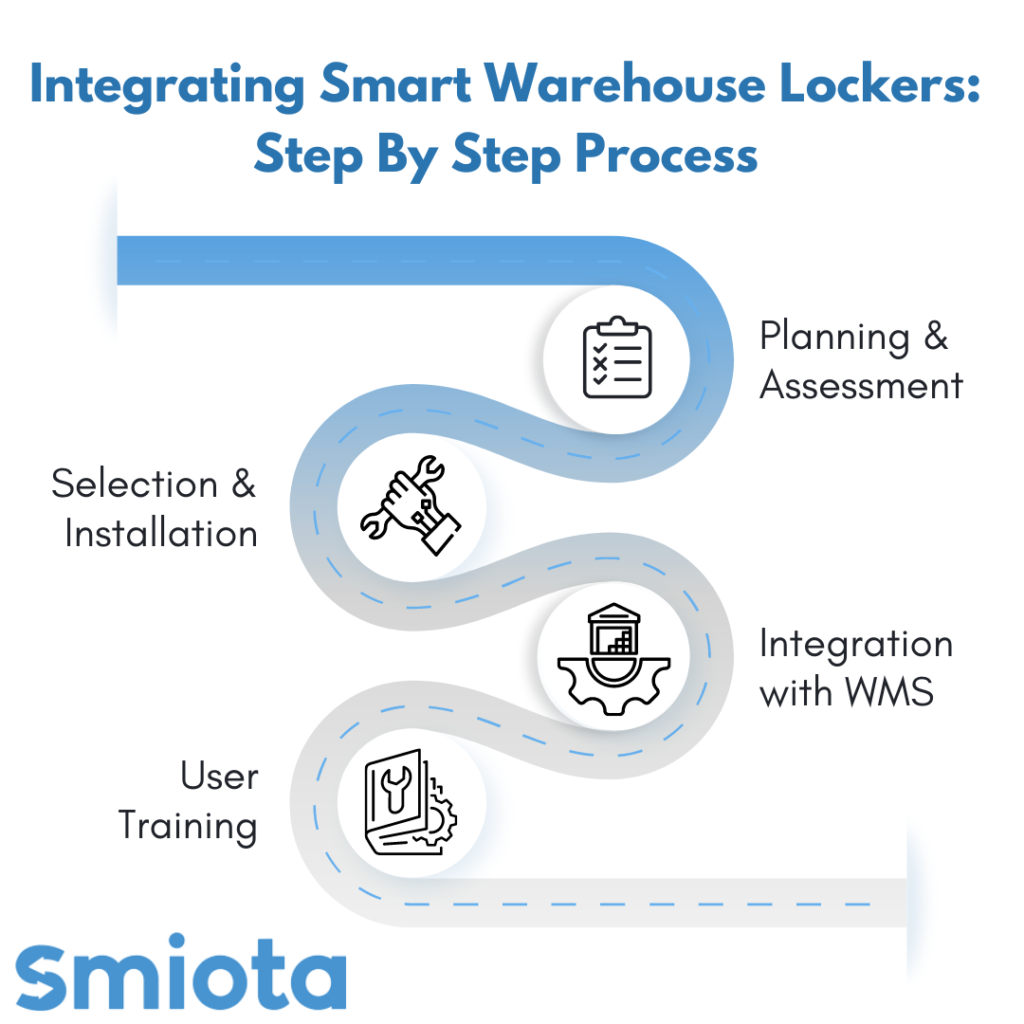

Integrating smart lockers into your existing warehouse operations requires meticulous planning. Here’s a breakdown of the steps involved:

- Planning & Assessment: Evaluate your current storage needs, identify inventory types that would benefit most from locker storage, and determine the optimal number and size of lockers required.

- Selection & Installation: Choose a reputable locker solution provider like Smiota that offers features tailored to your needs. The installation process can be completed with minimal disruption to your existing operation.

- Integration with WMS: Ensure seamless integration of the locker system with your existing warehouse management system (WMS). This allows for automatic data flow between the locker software and your WMS, maintaining accurate inventory records and optimizing picking processes.

- User Training: Provide training for your warehouse staff on how to operate the automated lockers, access specific compartments, and utilize associated features like item retrieval confirmation and real-time tracking.

Using Smart Lockers for Optimal Workflow

Smart warehouse lockers are improving warehouse operations and offer a variety of use cases beyond just storage:

- Storage of Picked Orders: Following picking, items can be placed in designated lockers for order fulfillment personnel who then pack and ship the orders. This reduces the risk of misplaced or lost items.

- Staged Storage: High-demand or frequently shipped items can be stored in easily accessible lockers, reducing travel time for pickers and expediting order fulfillment.

- Returns Management: Dedicated lockers can be used for customer returns, allowing for secure collection and streamlined return processing.

- Staff Management: Lockers can be assigned for employee belongings or tools, enhancing security and organization.

The benefits extend beyond standard use cases. Real-time tracking and analytics provided by smart lockers offer valuable insights for optimizing warehouse operations. Track inventory movement, identify areas for improvement in picking and packing times, and make data-driven decisions to further streamline your workflow.

Smiota’s Smart Warehouse Lockers: Features & Use Cases

Smiota, one of the leaders in smart locker solutions, offers innovative warehouse locker systems designed to enhance your operations. Here are some of Smiota’s locker features and how they can benefit your warehouse:

- Modular Design: Smiota lockers feature a modular design, allowing customization to suit your specific space and storage needs.

- Scalability: Easily add or remove lockers as your business grows, ensuring your storage solution adapts to your changing requirements.

- Access Control: Restrict access to specific lockers based on user permissions, ensuring the security of sensitive items.

- Real-time Tracking: Track inventory movement within the lockers in real-time, providing complete visibility into stock levels and streamlining picking processes.

- Data & Analytics: Gain valuable insights into inventory movement, picking times, and staff activity through comprehensive reports and analytics.

Smiota’s smart locker solutions cater to a variety of applications within your warehouse. Here are some specific use cases for Smiota’s smart lockers:

- High-Value Inventory Management: Securely store high-value inventory in designated lockers with restricted access control. Real-time tracking provides peace of mind and ensures accountability.

- Kitting & Assembly: Pre-assemble kits for specific orders within designated lockers, streamlining the picking and packing process for large or complex orders.

- Work-in-Progress (WIP) Management: Dedicate lockers for storing work-in-progress items, ensuring clear organization and efficient production flow.

- Climate-Controlled Lockers: Smiota offers climate-controlled locker options for storing temperature-sensitive inventory, maintaining product quality and ensuring compliance with regulations.

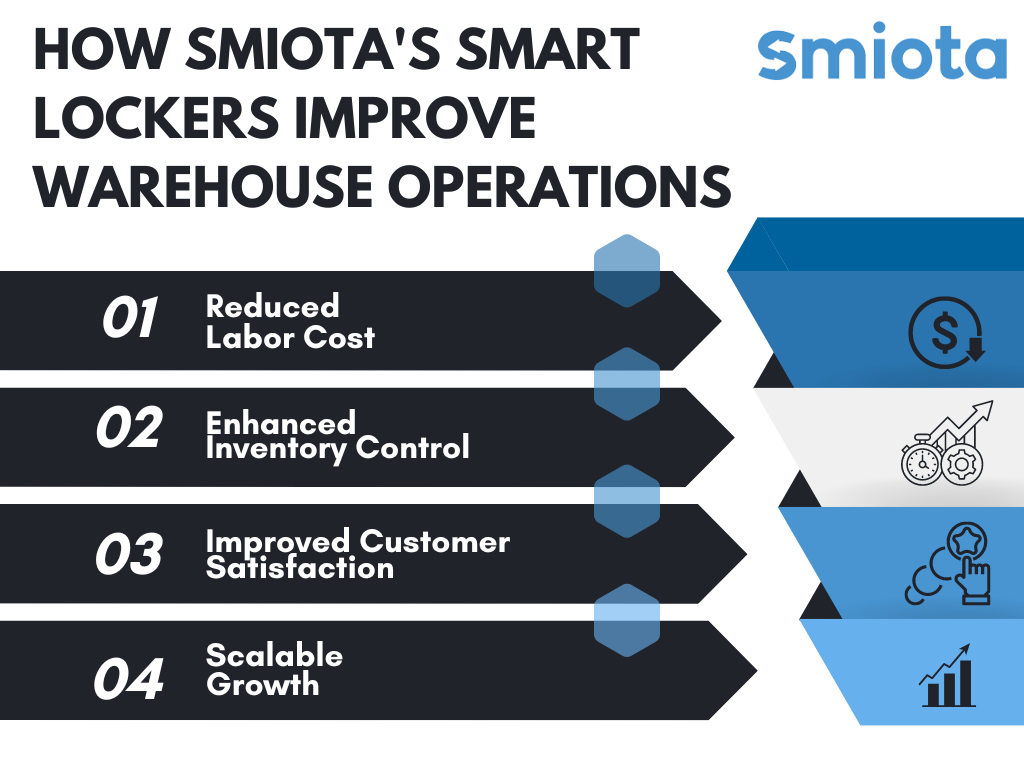

By leveraging Smiota’s smart locker features, you’ll experience:

- Reduced Labor Costs: Improved picking efficiency and reduced picking errors translate to lower labor costs associated with order fulfillment.

- Enhanced Inventory Control: Real-time tracking and data insights minimize stockouts and overstocking, reducing inventory carrying costs.

- Improved Customer Satisfaction: Faster picking and packing times lead to faster order fulfillment and happier customers.

- Scalable Growth: The modular and scalable nature of Smiota’s lockers allows your storage solution to adapt as your business grows.

Conclusion

Warehouse lockers are no longer a futuristic concept, but a practical and impactful solution for optimizing warehouse operations. By integrating smart lockers into your workflow, you can unlock a range of benefits – from increased efficiency and improved accuracy to enhanced security and data-driven decision making.

Smiota’s smart locker systems, with their customizable features and diverse use cases, offer a compelling solution for warehouses of all sizes and complexities.

Ready to take your warehouse operations to the next level? Contact Smiota today to discuss your specific needs and explore how our innovative smart locker solutions can transform your workflow.

![[Webinar] Streamline Your Supply Chain With Smart Lockers streamline your supply chain webinar](https://smiota.com/wp-content/uploads/2021/01/Streamline-your-supply-chain-with-smart-lockers-1-300x180.png)