The success of e-commerce and supply chain activities relies on something underestimated – the warehouse. Products flow from manufacturers to shelves, then into customers’ hands, all credit to the seamless operations within these storage hubs. But warehouses are more than just storage; they’re efficient business centers that act as the cornerstone of most manufacturing and distribution companies. They are pivotal in ensuring every order is picked with precision and shipped on time. This translates to satisfied customers and a healthy bottom line for the business.

However, cluttered layouts, manual processes, and inefficient picking methods can create bottlenecks, slowing everything down. This blog post is your guide to maximizing warehouse output. We’ll talk about warehouse efficiency tips, leveraging technology, and implementing smarter picking and layout strategies to improve warehouse operations, thereby reducing the TCO (Total Cost of Ownership) for warehouse owners.

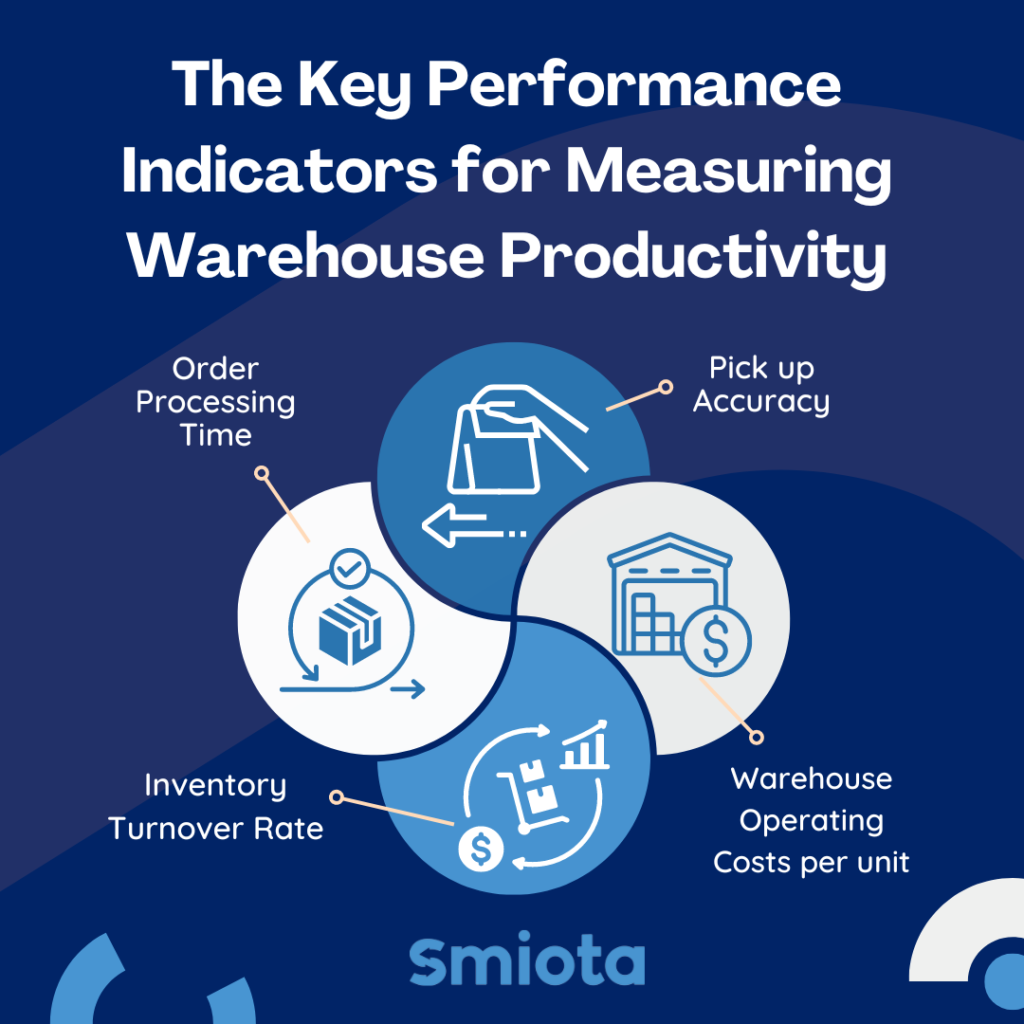

Measuring Warehouse Productivity: The Key Performance Indicators (KPIs) that Matter

An efficient warehouse is all about doing more with less. It’s about minimizing time, cost, and errors while maximizing order fulfillment rates. Here are some key metrics to track for improving warehouse efficiency:

- Picking Accuracy: Measured as a percentage of orders picked without errors. High accuracy translates to fewer returns and happier customers.

- Order Processing Time: The time it takes to process an order from receipt to shipment. Faster processing times lead to quicker deliveries.

- Inventory Turnover Rate: The number of times inventory is sold and replaced over a period. A healthy turnover rate indicates efficient inventory management.

- Warehouse Operating Costs per Unit: The cost of operating the warehouse per unit of product. Lower costs translate to higher profitability.

The Rewards of a Well-maintained Warehouse

Streamlining your warehouse operations isn’t just about ticking boxes; it brings a wealth of benefits that impact your entire supply chain. Here are a few key advantages of maintaining a well-operated warehouse:

- Increased Customer Satisfaction: Faster order fulfillment and fewer mistakes lead to happier customers, building brand loyalty and trust.

- Reduced Labor Costs: Streamlined workflows empower your team to work smarter, not harder, saving on labor costs.

- Improved Space Utilization: A well-organized warehouse maximizes storage space, allowing you to hold more inventory without needing additional space.

- Lower Inventory Carrying Costs: Optimized inventory management reduces overstock and out-of-stock situations, minimizing storage and lost sales costs.

- Enhanced Safety: Organized layouts and efficient processes minimize accidents related to cluttered aisles or improper item handling.

Actionable Tips to Transform Your Warehouse

Now that you know the importance of a well-maintained warehouse, let’s get to the point: how to improve warehouse efficiency and reduce costs. Here are some actionable tips you can implement to improve warehouse operations:

- Optimize Warehouse Layout: Analyze product movement patterns and design a layout that minimizes travel time for pickers. Using Smiota’s smart lockers is one of the ways to achieve this. By strategically placing smart lockers across the warehouse, asset handover can be finetuned in addition to optimizing device management and personal storage. Consider factors like high-demand items, pick frequencies, and product weight.

- Implement a Warehouse Management System (WMS): Implementing a WMS automates tasks like inventory management, order picking, and shipment routing. Think of it as the conductor of the warehouse orchestra, ensuring everything stays in perfect harmony.

- Improve Picking Processes: Consider zone picking, batch picking, or wave picking depending on order volume and product types. Zone picking assigns specific zones of the warehouse to pickers, while batch picking involves picking multiple orders simultaneously for related items. Wave picking involves picking items for a specific group of orders that will be shipped together. The key is to match the strategy to your workload for optimal productivity.

- Invest in Training: Train your staff on proper picking techniques, safety protocols, and efficient use of warehouse technologies. An empowered and knowledgeable workforce is essential for peak performance. For instance, Smiota offers its customers the necessary training and 24×7 customer support to operate its smart locker systems. This ensures that the staff understands how to utilize them effectively for picking, replenishment, and secure storage.

The Smiota Advantage: Smart Lockers for a Streamlined and Secure Warehouse

Smiota Smart Lockers have been a game changer for warehouses. These innovative solutions go beyond simple storage, offering a range of benefits to elevate your warehouse operations. Given below are some of the advantages of Smiota’s smart locker systems:

- Automated and Secure Access Control: Imagine a system where employees gain access to specific items using secure electronic credentials. No more lost keys or time wasted searching for the right one. Smiota’s smart lockers provide complete chain of custody and enhanced security, a key factor for warehouses handling high-value inventory. Access can be granted or revoked based on user permissions, ensuring only authorized personnel can access specific items.

- Streamlined Picking and Replenishment: Smart lockers can be designated for specific picking items. This reduces search time for pickers, ensuring accurate order fulfillment and faster processing times. Smiota’s PODs (Pickup or Drop-off) cater to a variety of needs, from dry packages to temperature-controlled environments, offering a versatile solution.

- Inventory Management and Control: Smiota’s smart lockers provide real-time inventory tracking, allowing for better management and preventing stockouts. Our Cloud Platform offers seamless integration with existing systems, allowing for easy data access and control. It helps to keep an eye on your inventory, preventing any surprises.

- Improved Staff Productivity: With smart lockers, staff spend less time searching for tools or equipment. They create a centralized and secure storage solution, boosting staff productivity and overall efficiency. Tools and equipment can be assigned to specific lockers, ensuring staff know exactly where to find what they need, minimizing time wastage.

- Enhanced Scalability: Smiota’s smart locker system is designed to grow with your business. Additional locker units can be easily integrated as your storage needs evolve. This scalability ensures your warehouse can adapt to fluctuations in order volume and product types.

The Smiota Difference: Beyond Just Hardware

Smiota offers more than just innovative hardware. We understand that a successful warehouse solution requires a comprehensive approach. Here’s what sets Smiota apart:

- Seamless Integration: Our Cloud Platform offers secure APIs for easy integration with your existing Warehouse Management System (WMS) or other warehouse software. This ensures a smooth workflow and eliminates the need for duplicate data entry.

- Customizable Solutions: We understand that one-size-fits-all solutions rarely work in warehousing. Smiota offers customizable locker configurations and software features to meet your specific needs. Whether you require temperature-controlled lockers or a system for managing high-value inventory, we can tailor a solution to fit your requirements.

- Exceptional Customer Support: Our dedicated team is here to support you every step of the way, from initial consultation to ongoing maintenance. We offer comprehensive training for your staff and ongoing technical support to ensure you maximize the benefits of your Smiota smart locker system.

Conclusion

The future of warehousing is a blend of efficiency, security, and exceptional employee experience. By implementing innovative solutions like smart lockers, warehouse managers can unlock a new level of performance. Smiota’s smart locker systems, combined with our commitment to seamless integration, customization, and exceptional support, enable warehouses to reduce costs and improve profitability.

Ready to Transform Your Warehouse with Smart Lockers?

Contact Smiota today to learn more about how our smart locker solutions can help you streamline operations, reduce costs, and elevate your warehouse to new heights of efficiency and security. Let’s work together to build a future where warehouses are not just functional, but strategic assets that drive business success.

![[Webinar] Streamline Your Supply Chain With Smart Lockers streamline your supply chain webinar](https://smiota.com/wp-content/uploads/2021/01/Streamline-your-supply-chain-with-smart-lockers-1-300x180.png)