The supply chain industry is a critical component of commerce, where efficiency and speed are paramount to ensure customer satisfaction. However, it faces numerous challenges, such as delays, inefficiencies, and the increasing demands of consumers. Micro fulfillment centers, enhanced by smart lockers, offer a novel solution to these issues, streamlining operations and improving service quality. This blog post explores the challenges within the supply chain, the distinction between fulfillment centers and warehouses, the emergence of micro fulfillment centers, and the integral role of smart lockers.

Challenges in Supply Chain

Addressing traditional supply chain barriers in the rapidly evolving logistics sector is pivotal for achieving inventory success and real-time order management. The primary challenges include:

Increased Consumer Expectations

Consumers today expect rapid deliveries and real-time updates, pushing supply chains to become faster and more reliable, increasing the pressure on supply chains to be both quick and efficient while still providing top-notch service.

Globalization and Extended Supply Chains

As companies go global, their supply chains stretch further, adding complexity. This involves handling regulatory challenges, navigating international trade, minimizing disruption risks, complicating inventory management, raising transport costs, and delaying deliveries.

Fluctuating Demand and Inventory Management

Predicting market demand is increasingly complex, with trends shifting rapidly. Supply chains must stay flexible to cope with these changes without facing high costs. Incorrect stock levels can result in lost sales, lower profits, and customer dissatisfaction.

Sustainability and Ethical Practices

There’s growing pressure on businesses to be environmentally responsible and ethically sound. Sustainable practices are crucial, involving lower carbon emissions, ethical sourcing, and waste reduction. Adapting to these practices requires significant changes in supply chain operations.

Technological Integration and Cybersecurity

Adopting new technology is vital for enhancing supply chain efficiency, transparency, and reliability. However, this integration can be challenging and expensive. Moreover, digitalization increases vulnerability to cyber threats, highlighting the need for strong cybersecurity measures.

Logistical Challenges and Last-Mile Delivery

The final delivery leg is often the most costly and complicated. Challenges like urban congestion and the demand for flexible delivery options make last-mile logistics difficult.

In response to these challenges, the logistics sector is innovating with solutions like fulfillment centers, which evolve further into micro fulfillment centers with the integration of smart lockers. But first, we will look at the differences between fulfillment centers and traditional warehouses.

Fulfillment Centers Vs. Warehouses

Fulfillment centers and warehouses play pivotal roles in storing and managing inventory. However, their functions, operational focus, and impact on the supply chain differ significantly.

Warehouses: The Traditional Storage Hubs

Warehouses primarily serve as storage hubs for goods and products over extended periods. They are the critical nodes in the supply chain where inventory is stored until it is needed for distribution. The function of a warehouse is to safely and securely store large quantities of goods, ensuring they remain in optimal condition until they are moved. Warehouses are characterized by their physical footprint, often located in industrial zones or near transport hubs to facilitate easy movement of goods. Their operations focus on inventory management, storage optimization, and goods preservation.

Fulfillment Centers: The Agile Distributors

On the other hand, fulfillment centers are high-energy environments where goods are not just stored but also picked, packed, and shipped directly to the customer. These centers handle both B2B and B2C orders, processing them with remarkable speed and efficiency. Fulfillment centers are the heart of e-commerce logistics, where the focus is on reducing the time it takes for an online order to reach the customer’s doorstep. Their operations leverage advanced technologies and automated systems to manage inventory, process orders, and handle returns swiftly, focusing on quick product turnaround and emphasizing speed and accuracy in customer satisfaction.

The limitations of traditional warehouses and fulfillment centers have catalyzed the rise of micro fulfillment centers, marking a pivotal shift towards customer-centric supply chain solutions. Innovations like micro fulfillment centers that use smart lockers, aim to enhance delivery speed, convenience, and efficiency.

The Shift to Micro Fulfillment Centers and Smart Lockers

The evolution of supply chain dynamics in response to the surge in e-commerce and the demand for faster delivery times, has led to the rise of micro-fulfillment centers. These centers are smaller, more agile versions of traditional fulfillment centers, often situated closer to the end consumer to enable rapid delivery of goods. Micro fulfillment centers leverage high-density storage solutions and advanced automation technologies to maximize efficiency in a compact footprint. Integrating smart lockers into this model enhances the efficiency and convenience of deliveries.

The Role of Smart Lockers in Micro Fulfillment Centers

The role of smart lockers in micro-fulfillment centers is multifaceted, touching on operational efficiency, security, customer service, and space optimization. They act as a critical interface between the digital and physical realms of the supply chain to meet the evolving demands of the market.

- Operational Efficiency: Smart lockers automate inventory storage, retrieval, and management, integrating with warehouse systems for real-time tracking and quick access for fulfillment.

- Security: They offer a secure storage environment with controlled access and surveillance, reducing theft, damage, or loss risks.

- Customer Pick-ups: For direct consumer pickups, smart lockers provide a contactless, efficient method for collecting orders.

- Returns and Exchanges: They facilitate easy drop-off points for customer returns and exchanges.

- Space Optimization: Their compact, modular design maximizes storage capacity in limited spaces, enabling vertical stacking.

- 24/7 Operations: Automation allows for continuous operation without constant staffing, which is crucial for meeting e-commerce demands.

By leveraging the capabilities of smart lockers, these centers are better equipped to handle the complexities of distribution and fulfillment in today’s retail environment.

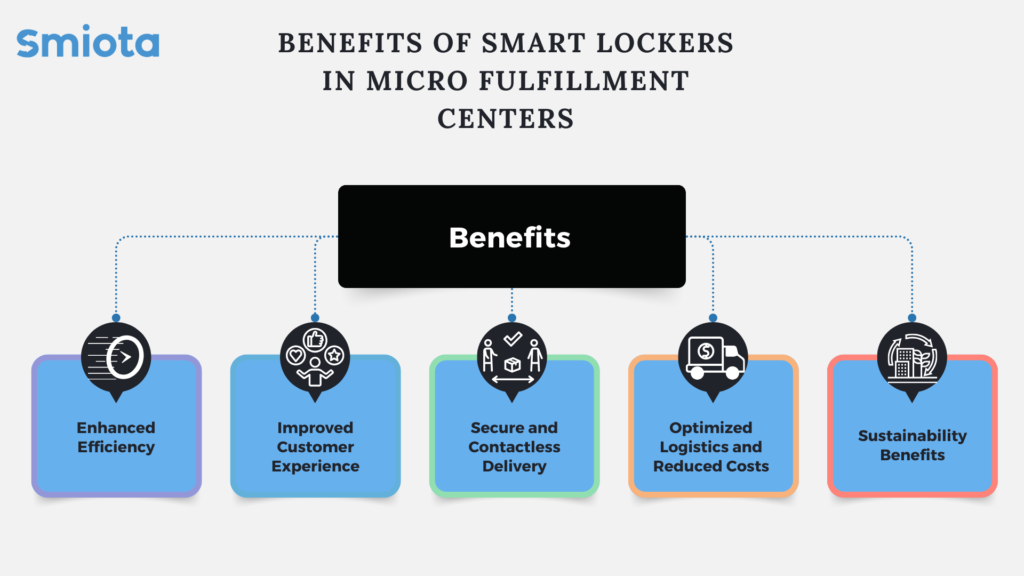

Benefits of Smart Lockers in Micro Fulfillment Centers

Integrating smart lockers into micro fulfillment centers is a testament to the innovative approaches being applied to solve traditional supply chain issues. Smart lockers act as a bridge between the efficiency of micro fulfillment centers and the final delivery to customers by offering the following benefits:

Enhanced Efficiency with Smart Lockers

Smart lockers improve the fulfillment process, enabling faster pick-up and reducing errors by minimizing human involvement, thus increasing package fulfillment capacity.

Improved Customer Experience

Micro-fulfillment centers with smart lockers improve satisfaction by offering 24/7 access, allowing users to pick up orders at their convenience without depending on operational hours and staff, and reducing missed deliveries.

Secure and Contactless Delivery

These parcel lockers offer a secure, contactless option for receipt, appealing to health-conscious users by minimizing direct human contact and ensuring parcel security.

Optimized Logistics and Reduced Costs

Smart lockers cut logistics costs by centralizing pick-ups and enabling batch deliveries, reducing the number of delivery trips, fuel consumption, and vehicle wear, improving route efficiency, and lowering expenses.

Sustainability Benefits

They support sustainability by reducing emissions and packaging waste, as fewer delivery attempts decrease transportation needs and eliminate the need for additional packaging, lessening waste.

Incorporating smart lockers into micro fulfillment centers significantly boosts logistical operations, diminishes operational expenditures, and elevates the user experience by providing flexible, secure, and contact-free delivery solutions.

Conclusion

Micro fulfillment centers and smart lockers set new standards for supply chain efficiency and customer satisfaction. This innovative approach not only mitigates traditional logistics challenges but also leverages technology to adapt to changing market demands. As the need for agile and sustainable logistics solutions grows, the synergy between smart lockers and micro fulfillment centers will continue to play a crucial role in the evolution of global commerce, driving improvements in service delivery and operational efficiency.